1. This is what it looks like

Apart from some wear on the chrome, it looks pretty good. However, one of the shutter clothes was defective and it was generally quite stiff.

But it is also the most complicated of all Zorkis when it comes to overhauling; no other model is likely to have had more parts installed in it.

2. Remove external parts

Let's start taking it apart. As usual, we'll start by removing the cover.

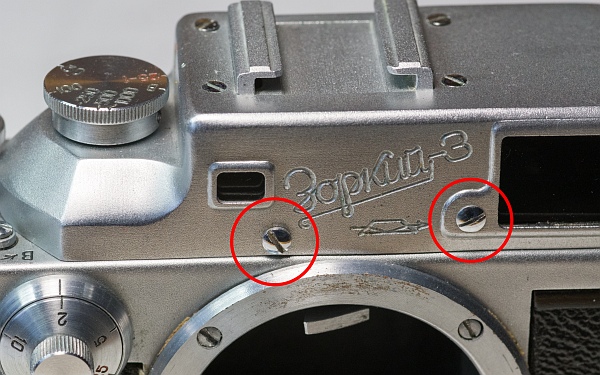

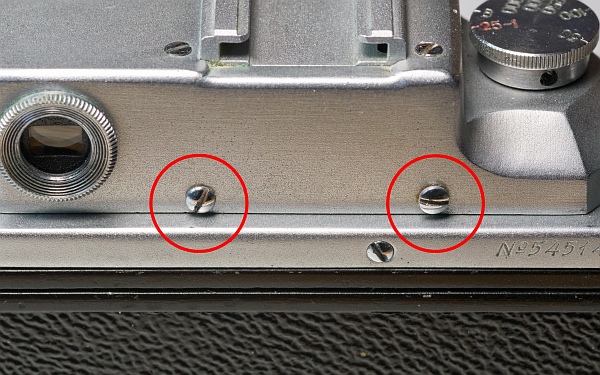

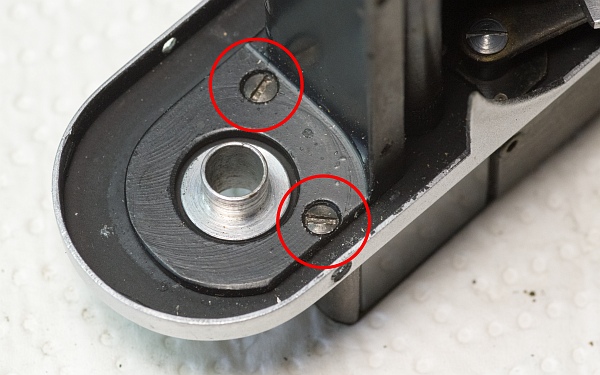

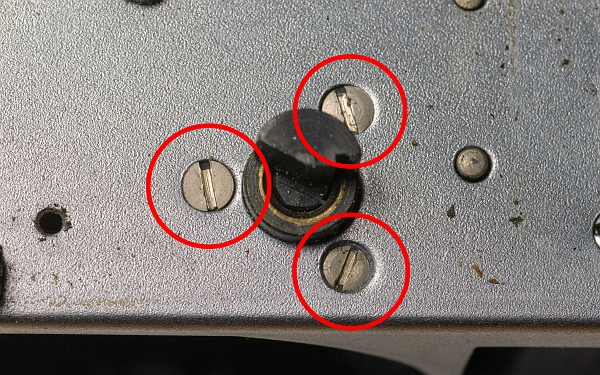

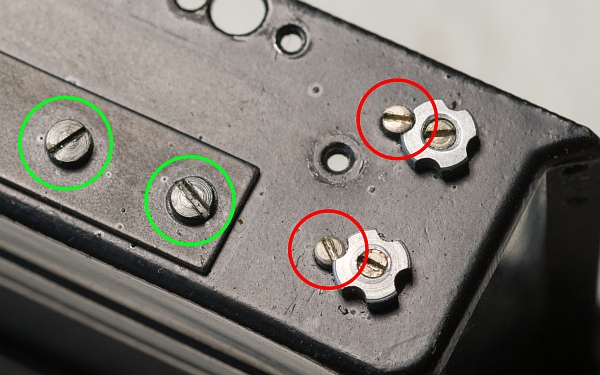

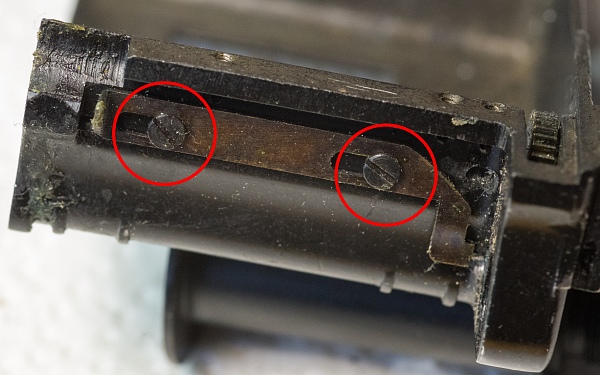

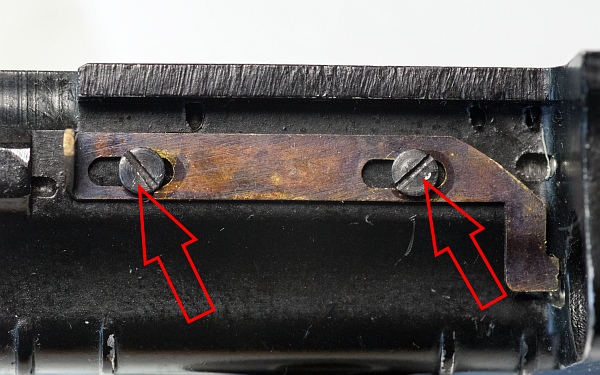

Loosen the two screws on the front and back of the cover (left).

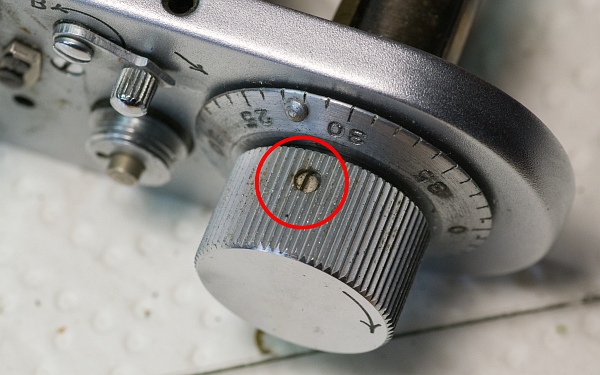

Then remove the two grub screws in the speed button. It can then be removed (bottom).

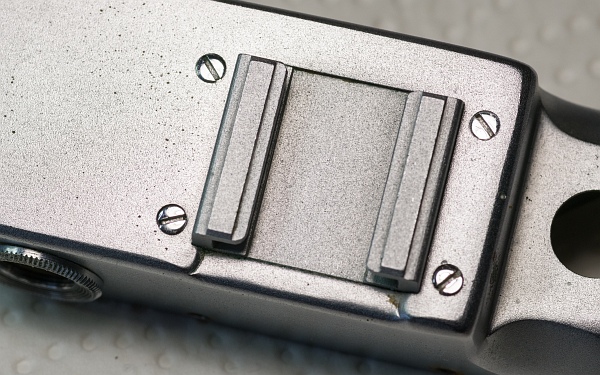

After removing the 4 chrome-plated screws, the accessory shoe can be removed from the cover (bottom).

Rewind crank and speed wheel

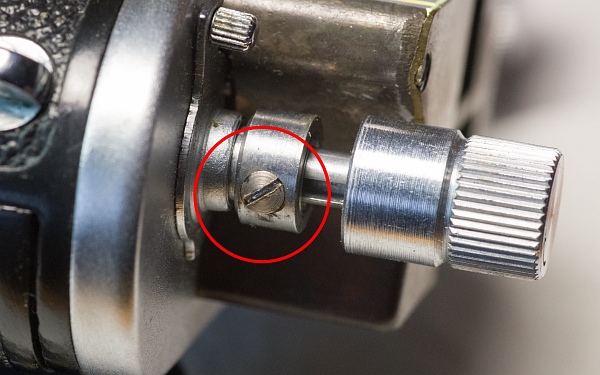

Remove the screw and disassemble the rewind crank as usual (left).

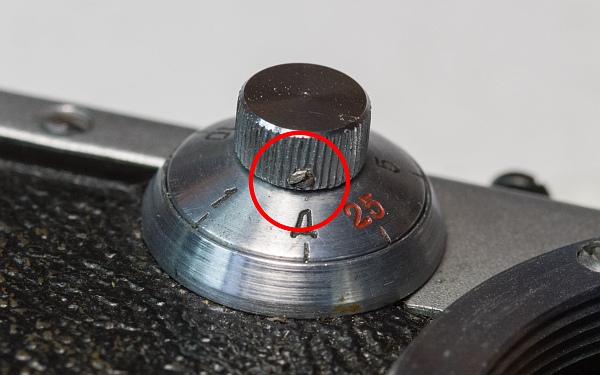

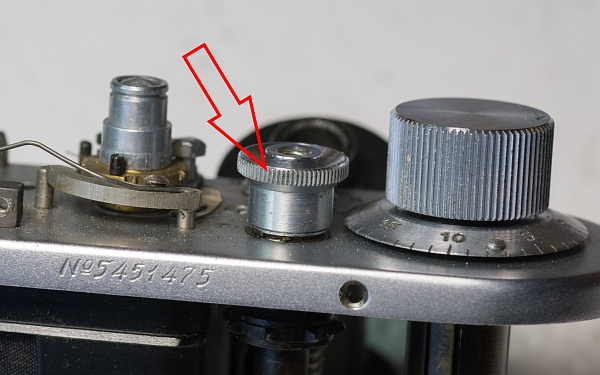

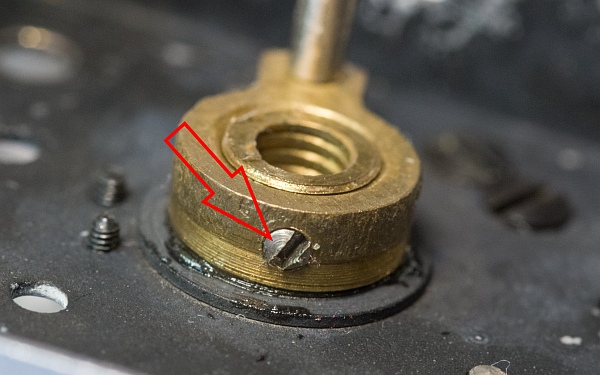

The knob for adjusting the slow speeds on the front is secured with a tiny grub screw (bottom left).

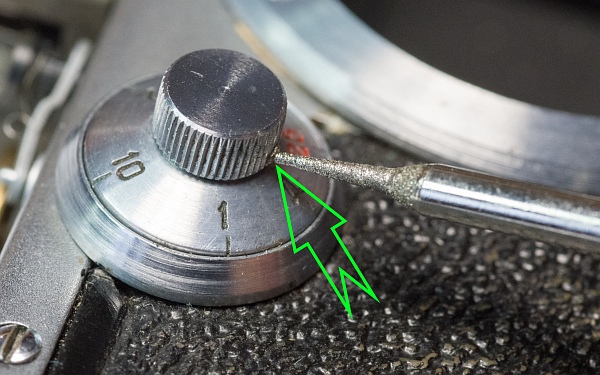

Unfortunately, this screw had a defective head, so I had to mill it out with a Dremel (bottom).

3. Remove housing

The lens mount, the housing, and the inner cover plate with the slow speed button must be removed.

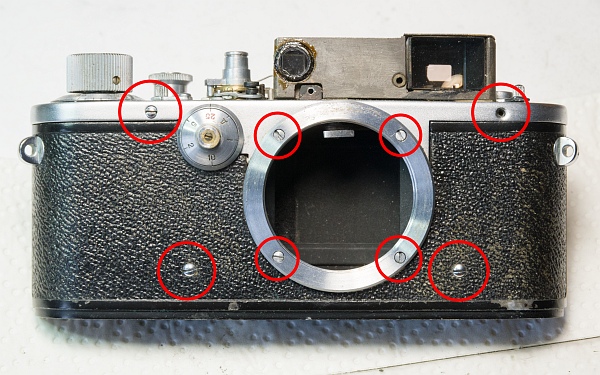

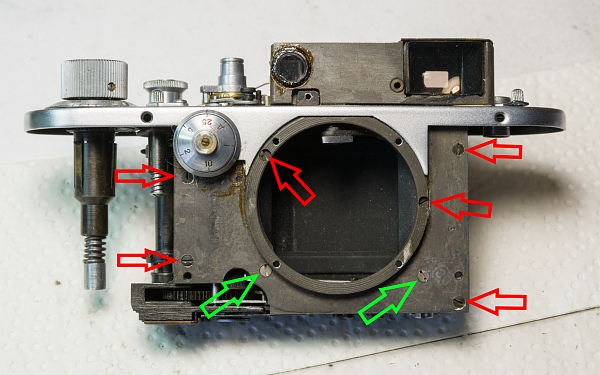

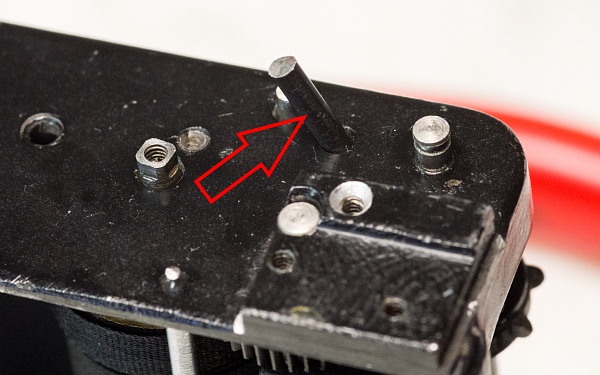

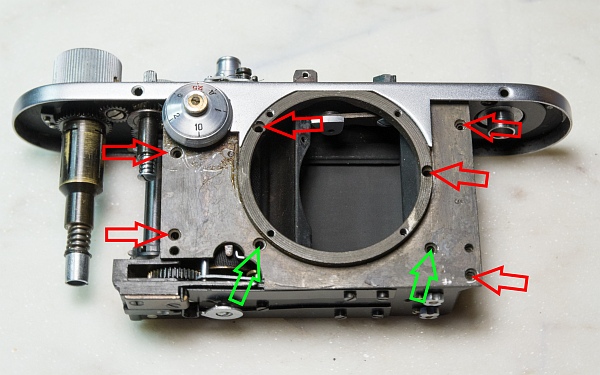

The 4 screws on the lens mount and the 4 screws holding the housing in place must be removed (left).

Wax paper discs are visible under the lens mount. These are used to precisely adjust the flange focal distance to 28.8 mm. Sometimes they are missing, which means that an amateur has not reinstalled them...

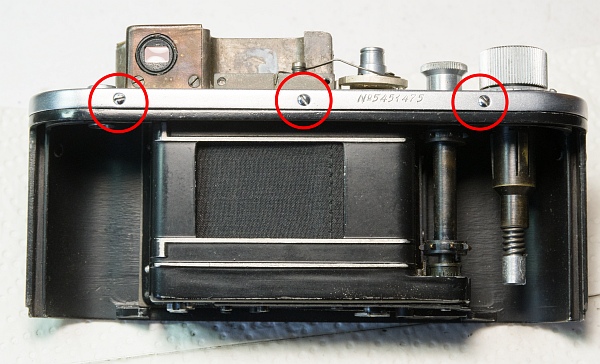

Now remove the 3 rear housing screws (bottom left).

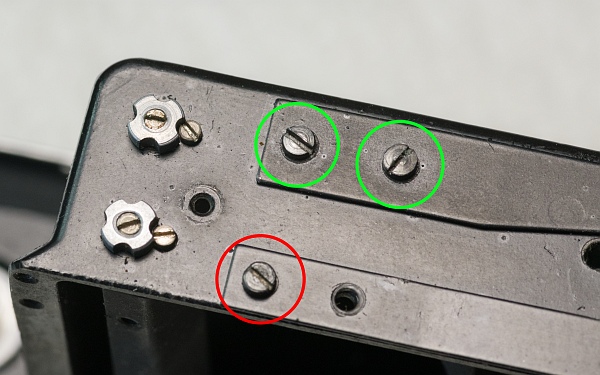

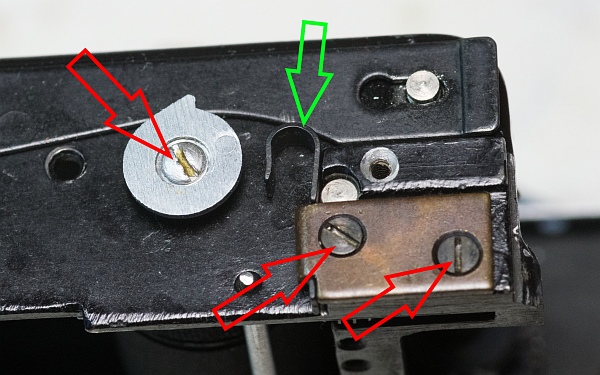

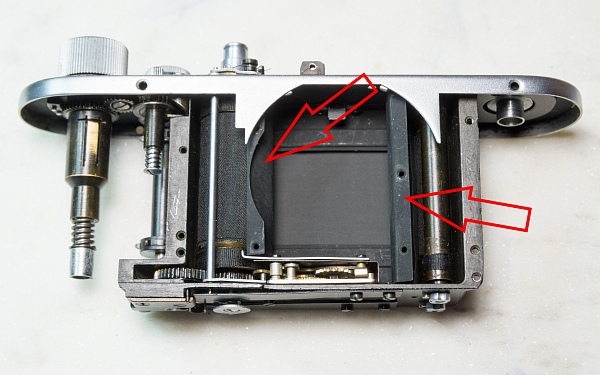

Underneath is the inner cover plate with the slow speed wheel, which is held in place by 8 screws. After removing the screws, the plate can be removed with a little fiddling. The two screws marked in green are shorter and must be replaced in exactly the same position during reassembly (bottom).

4. Remove rangefinder

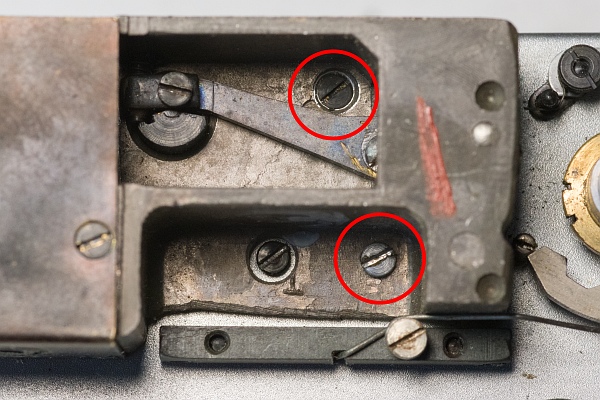

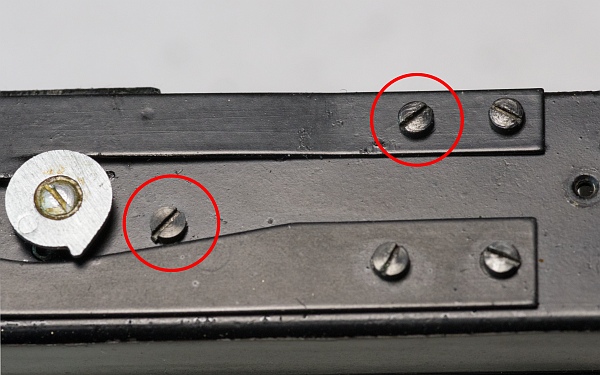

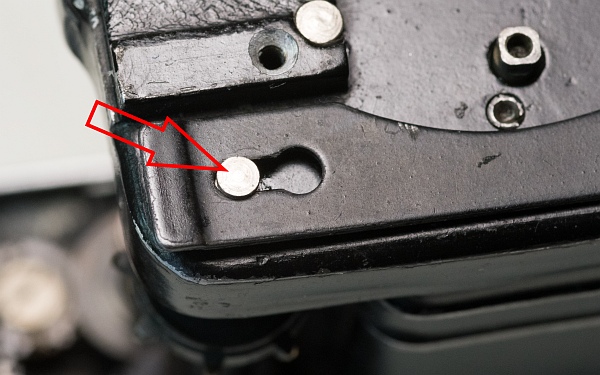

Before the shutter can be removed, the rangefinder must first be removed from the camera. Underneath it, one hidden screws is revealed that holds the shutter in place from above. First, unscrew these two screws.

Then unscrew the two marked screws on the underside. The rangefinder can then be removed by lifting it upwards.

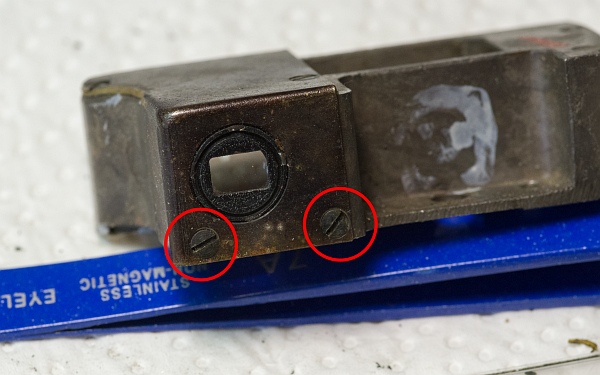

The viewfinder unit of the rangefinder has a cover plate that can be removed. Loosen the four screws (2 at the back, 2 at the top) and remove the cover.

Inside is the sliding lens for diopter adjustment. It can now be easily removed and cleaned. This also allows you to access the glass surfaces of the viewfinder.

The two screws that hold the shutter in place from above are now visible. In addition, the lever that moves the diopter lens can now be removed.

The rangefinder arm can be removed after removing the 3 screws.

5. Remove shutter

To remove the shutter, we need to make a few preparations.

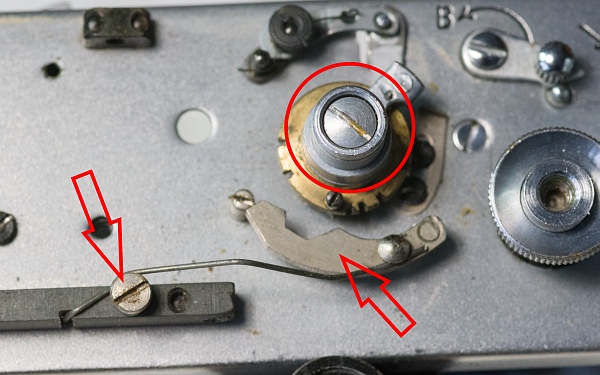

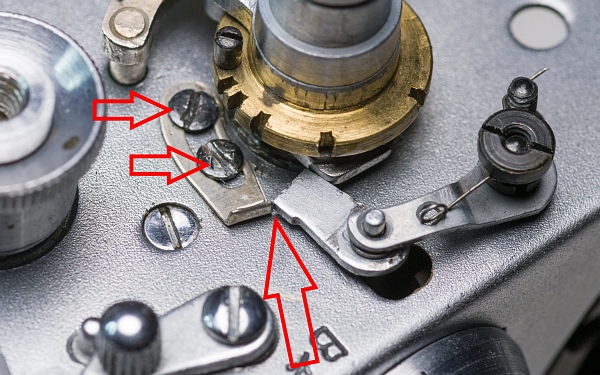

These two screws hold the slow speed mechanism in place. Once the slow speed mechanism has been removed, the two shielding plates inside can finally be removed (left).

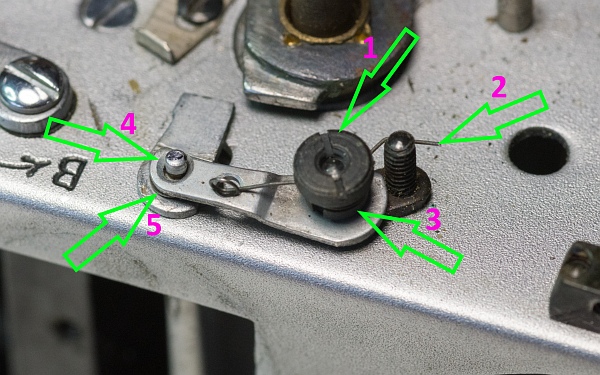

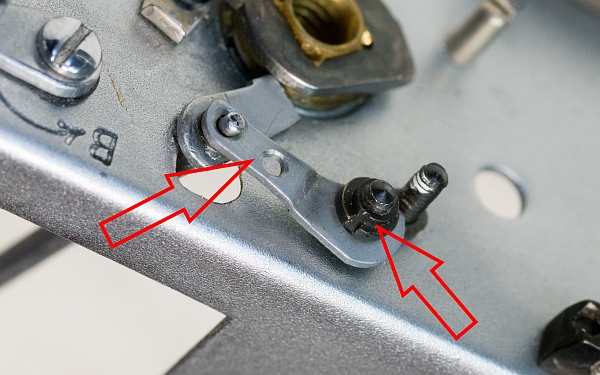

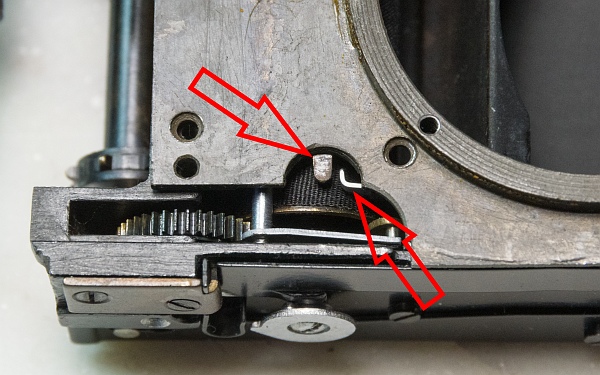

The screws on the left and bottom hold the release spring of the slow speed mechanism and the brake for the first curtain (the U-shaped part and the comma-shaped wheel in the middle) (bottom).

The two screws marked in green hold the release spring of the shutter. It can be removed now or later.

Now the parts of the speed control are dismantled. The broken drive pin then becomes visible underneath.

First remove the speed control lever. A spring will appear under the large screw. Also remove the spring that holds the speed delay lever and the lever itself (left).

Underneath, you will see the disc with the notches for the different speeds. It is held in place by a long grub screw. The disc itself can be very tight and sometimes needs to be levered off. Be careful not to scratch the housing! (bottom left)

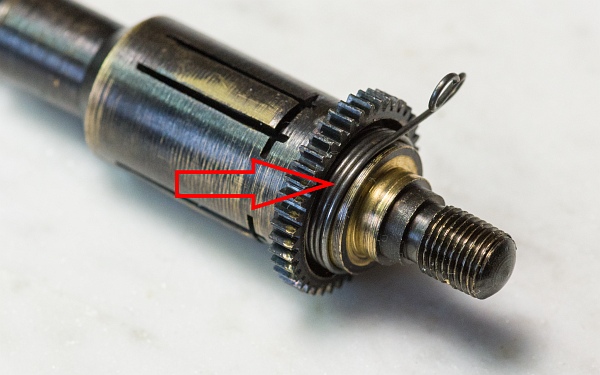

The broken driver can be seen below. This causes all times to run with the curtain closed. The position of the driver must be marked when the camera is cocked for reinstallation (e.g., with small scratches or a felt-tip pen) (below).

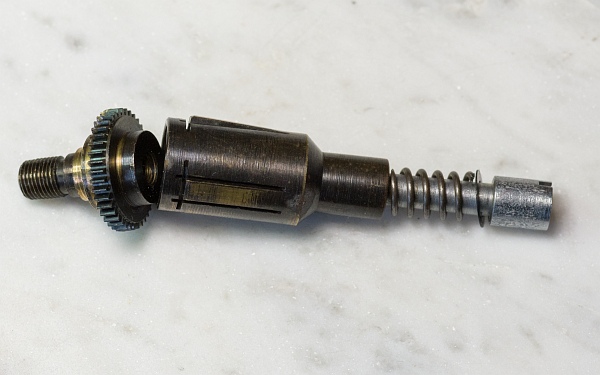

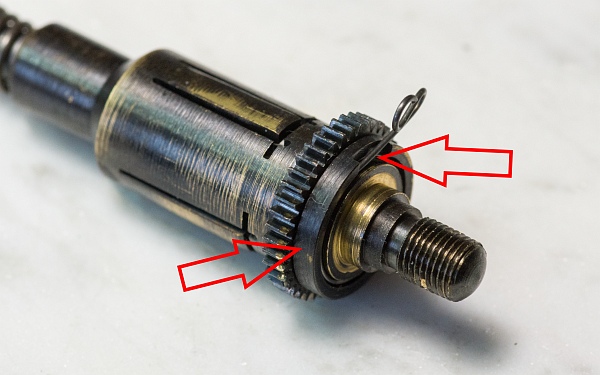

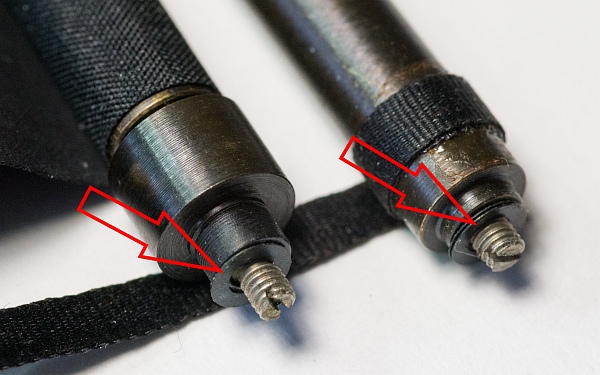

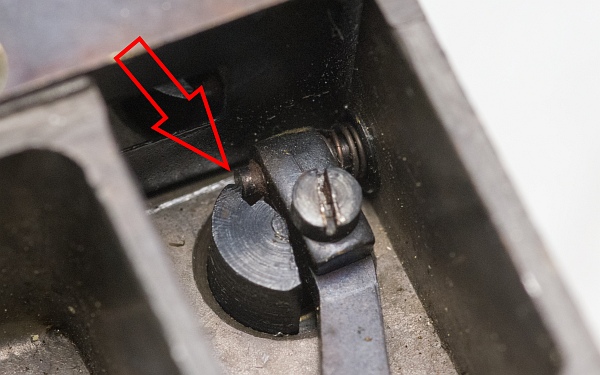

The counterpart to the broken drive pin on the underside. It consists of two parts that are secured with a grub screw (left).

After removing the grub screw, the two parts can be unscrewed. They are quite tight, but this can be done with small pliers and rubber gloves.

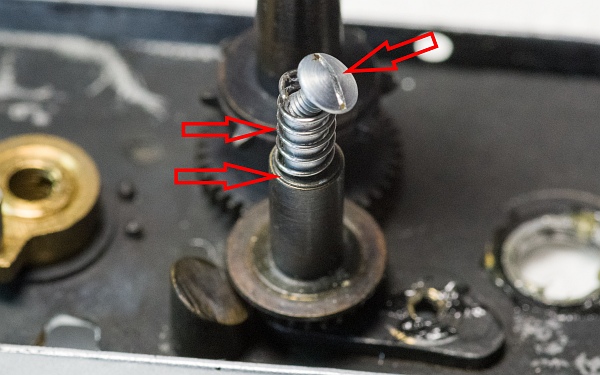

Now release the shutter springs: Remove the small locking screws, hold the inner screw in place with a screwdriver, and loosen the notched nut clockwise (!) with a small pair of pliers. The springs will then usually release by themselves. We will only remove the nuts after the shutter has been removed.

Now also unscrew the screws on the release spring (marked green) and remove the spring.

After removing the two silver screws on the top that hold the shutter in place, the shutter case can be carefully removed.

6. Remove other parts

The control system for the slow speed mechanism is now being dismantled.

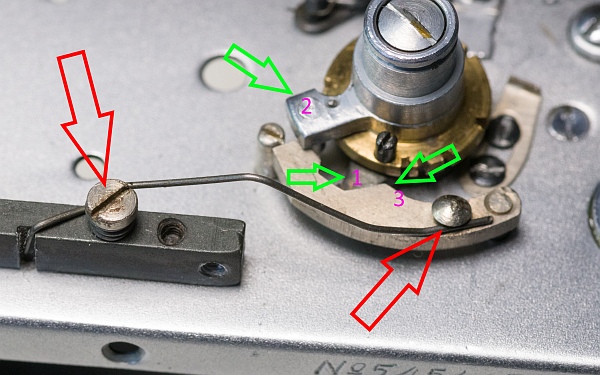

1 Unscrew the upper nut; this should be quite easy.

2 Now the spring holding the linkage can be removed.

3 Underneath is another nut holding plate 4.

4 Now the plate can be removed.

5 A tiny washer (barely visible) will appear.

Now the rod leading to the slow speed mechanism can be removed with a little fiddling.

Release button and winding knob.

Remove the release button by unscrewing it (left).

The rewind lock is now removed. After loosening the screw, you will see a wedge-shaped part on the underside. There are also small washers for adjustment (usually 2 to 3 pieces) (bottom left).

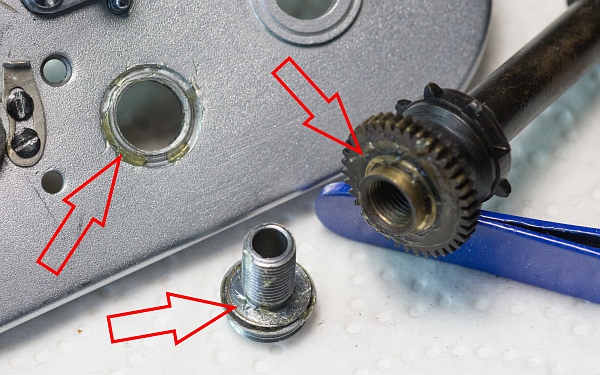

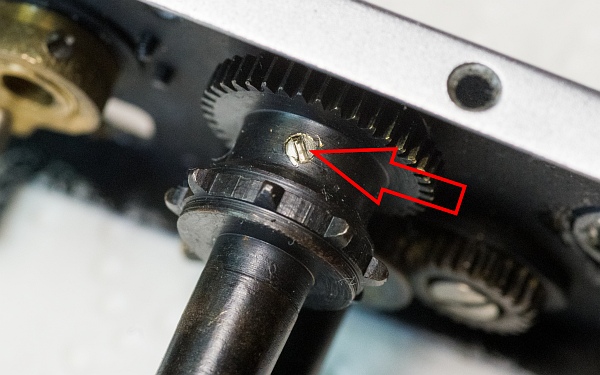

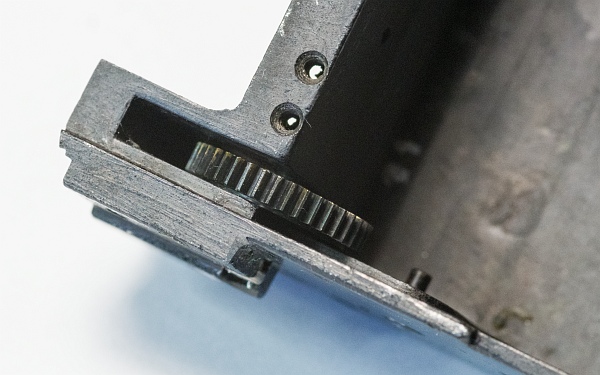

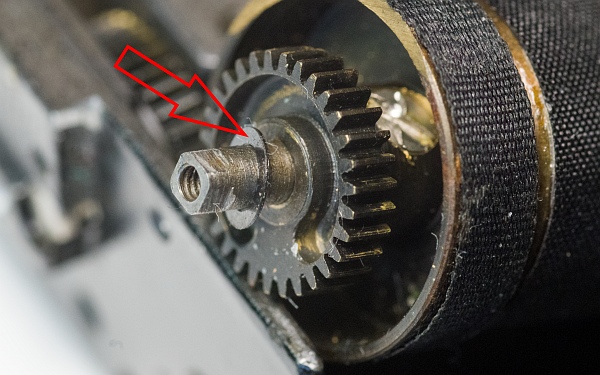

Remove the grub screw and turn the winding knob counterclockwise. Hold the gear wheel at the bottom so that the spring, which prevents the tensioned shutter from unwinding by itself, is not overstretched (bottom).

Remove the two screws. The entire winding knob can then be removed and further disassembled (left).

The gears and rewind lock must be removed.

This screw holds part of the rewind lock in place. After loosening the screw, you will see a spring and a small washer. The gear wheel can then be removed (left).

Another gear wheel must be removed. The screw has a standard thread, but can be quite tight (bottom left).

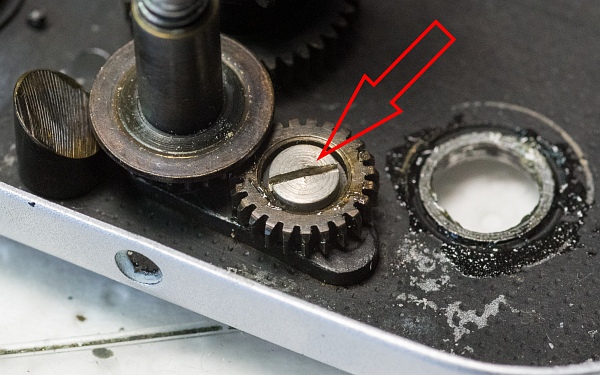

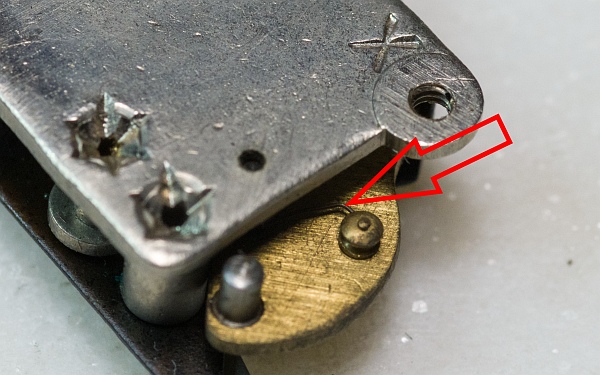

The small grub screw holds the spiked roller in place. After removing it, you can unscrew the spiked roller from the upper silver part (bottom).

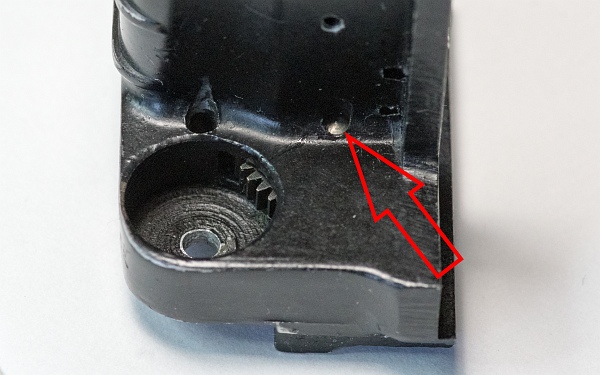

The arrow points to a pin that has been inserted through the axle of the large gear wheel. It can be easily pushed out (bottom left).

The part on the housing is used to transfer the rewind lock to the release spring so that the spiked roller is released to wind up the film. It then pushes a small rod downwards (at the very bottom).

More things.

The broken driver and what it looks like when it's intact. Fortunately, I had a defective Zorki 3 with total damage (warped top plate) from which I could remove the part. You can't use one from a Zorki 4 or 3M either, because they don't have the upper cam that is needed to delay the long exposures (left).

Below: The disc at the top right has a small cam on the inside. This is used to set the slow shutter mechanism to 1/10 sec. At 1/10 sec, the mechanism is switched to a different mode, which is why the 1/10 sec sounds different.

At the bottom left, the rod is in the 1/10 sec. position and thus pulls on the small lever in the slow motion mechanism.

Below, the lever is in the position for all other slow motion speeds.

7. All relevant parts in the overview

After cleaning, I photographed the relevant parts individually and numbered them. I will refer back to the numbering when reassembling.

Since there are quite a lot of parts, I have moved them here.

A few cleaning tips: The best way to remove decades of dirt from metal parts is to use lighter fluid and a toothbrush. I then place the parts in an ultrasonic bath to remove any remaining dirt and grease. I then polish the chrome parts with polishing cotton wool; NevrDull has served me well in this regard so far.

8. Reassembly

Driver and lever of the rewind lock.

Grease the hole for the driver slightly. Then take Parts 19 and screw them together so that the grub screw can be screwed back in. The whole thing should move very easily. Das Ganze sollte sich sehr leicht bewegen lassen.

Reinstalling the rewind lock lever requires a little patience. You have to push the wedge-shaped part of Parts 16 through the hole from below in the correct position. The washers must be reinserted beforehand. Then the lever must be positioned at the correct angle on the square pin and, last but not least, the screw must be screwed in. Practice makes perfect here...

Reassemble the gears.

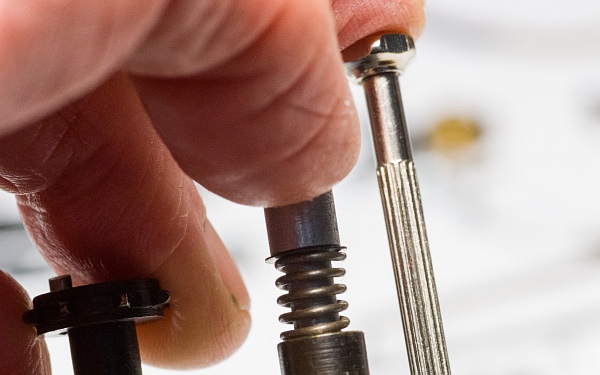

Use Parts 26. Apply some grease to both parts and to the ring on the top. Now screw the two parts back together loosely so that there is enough space to reinsert the rewind lock gear (left).

Then apply some grease to the axle and underneath the gears. The green arrow marks the wedge-shaped part of the rewind lock. It should be in this position when the rewind lock is not activated, i.e. when the lever at the top is not set to “B” (bottom left).

Reinsert the rewind lock gear, put the washer and spring in place, and screw the screw back in (Parts 9) (bottom).

Reinsert the small gear wheel from Parts 15 and apply a little grease to the screw (bottom left).

Now the spiked roller can be screwed tightly to the upper part and the grub screw can be screwed back in (bottom).

The winding knob must be reassembled.

Required are Parts 8. The left-hand image shows the order in which the individual parts must be assembled. Place the washer and spring onto the threaded rod, then insert it through the sleeve and screw it to the gear wheel.

The spring, which prevents the tensioned shutter from running off by itself, must be put back on the right way round (bottom left).

Then slide the small ring over the spring with the notch facing upwards. The spring must lie in the recess (bottom).

Now insert the winding knob and use a special technique: insert a small screwdriver through the threaded plate and the eyelet of the spring. Hold your fingers as shown, turn the whole thing around, and you can now insert the screws again from above. A real finger exercise (bottom).

Now let's reassemble the winding knob on the top (Parts 2). First, clip the small spring back into place. It provides resistance for the film counter wheel.

Spread some grease around the thread.

Now place the disc with the collar facing up and the film counter disc on top. Screw the winding knob back on and secure it with the grub screw.

Preparations for installing the shutter.

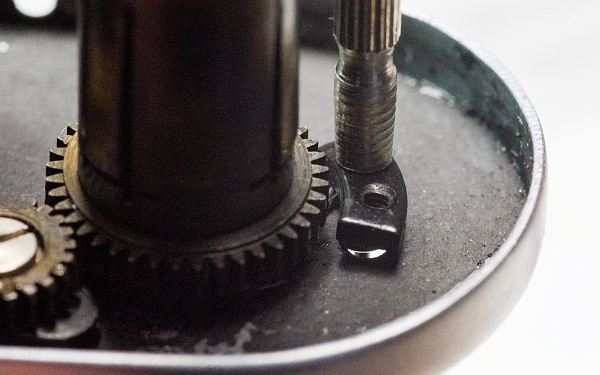

Required are Parts 32. Position the gear wheel and reinsert the pin. A small drop of oil on the axle will not hurt (left and bottom left).

Required are Parts 11. The slider for the rewind lock should move easily (bottom).

At the very bottom: The washers are reattached as they were found.

For reassembling the shutter and cutting the cloths to size, please refer to here. The process is very similar and does not need to be repeated here.

However, one detail has been changed. The pin for the end stop of the shutter mechanism is no longer located under the gear wheel in the shutter box, but under the large drum (recognizable by the milled groove at the very bottom of the gear wheel). The gear wheel in the shutter case now turns freely. The advantage of the new solution is that it is much easier to install the shutter, as it is now virtually impossible to insert the large drum incorrectly.

Slow speed mechanism.

Required are Parts 24. First, reinsert the rod through the hole at the top and then replace the tiny washer (left).

Then place the plate on top and tighten it with the smaller of the two nuts (bottom left).

Now reinsert the spring, secure it with the larger of the nuts, and clamp it behind the screw on the right (bottom).

Assembling the speeds setting.

Required are Parts 22 and 23. Replace the brass speeds disc and secure it with the grub screw – which can be a fiddly job (left).

Then put the silver knob on, insert the spring, and tighten it with the screw. Make sure that the spring is not pinched by the screw (bottom left).

Now reinsert the lever. This is a bit fiddly because you have to insert the rod into a hole at the bottom. Then secure the spring again and place it on the lever as shown (bottom).

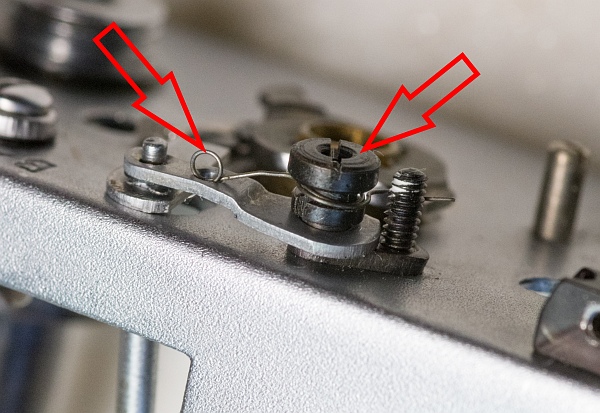

How it works: When triggered, the lever is pressed down by the spring and blocks the driver (1). The first curtain runs down, the silver knob (2) turns and hits the corner (3) of the lever. The lever springs back and releases the driver (1) so that the second curtain can run down.

Sometimes it happens that all speeds rush through at 1/1000 sec, even though everything seems to be fine. Often the lever is slightly bent or is not at a right angle to the rod. You can then carefully bend the lever back into shape.

Light shield, release spring, and brake.

Required are Parts 13, 14 and 17. Do not forget to reinsert the rewind lock pin (left).

The release spring is hooked into the release pin and pushed into position (bottom left). Then you can place the large light shield in the housing.

Now it gets a little tricky. The screw must be inserted through the rear hole of the release spring, through the housing, through the hole in the light shield, and then screwed into the small threaded plate (bottom).

The parts of the first curtain brake are reinstalled. The comma-shaped disc in the middle must be positioned exactly as it is when the shutter is cocked.

Installation and adjustment of the slow speed mechanism.

If the slow speed mechanism Parts 10 is not working properly, first check whether the small spring is unhooked. It must be in this position (left).

Now you can insert the metal shields and only then reattach the slow speed mechanism. It shares a screw with the release spring. Then reinsert the front plate as usual and screw it in place. Reminder: The shorter screws belong in the green arrows (bottom).

Bottom left: The lever (left arrow), which is responsible for switching between 1/10 sec. and the other speeds in the slow speed mechanism, must be placed to the right behind the hook (right arrow). This is a bit fiddly.

Now you can set the slow speeds. Set the 1/5 sec. If it is too fast, turn the screw in the long exposure knob in slightly; if it is too slow, turn it out slightly. Try out all the long speeds, including "T". The bottom picture shows how the delay lever in the "T" position comes against the small plate with the collar. If you then turn the wheel back to 1 sec., the curtain should close again.

If "T" does not work, the small plate can be adjusted in position with the two screws (at the very bottom).

Rangefinder and the rest.

Installing the rewind crank (Parts 6): First place the black washers inside the shutter, then put the washer and spring on the fork. Insert it into the housing from below and put the ring on. Then insert the knob of the rewind crank into the fork and screw it in place (left).

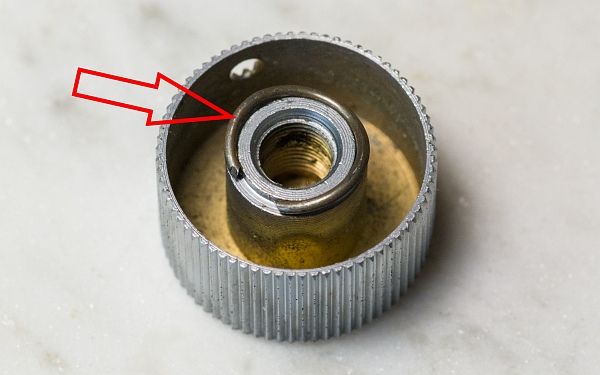

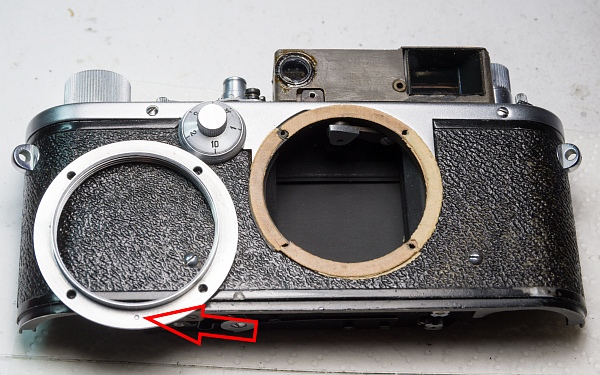

The wax paper discs must be replaced exactly as they were removed during disassembly. Then attach the threaded ring (Parts 18). The mark must be at the bottom.

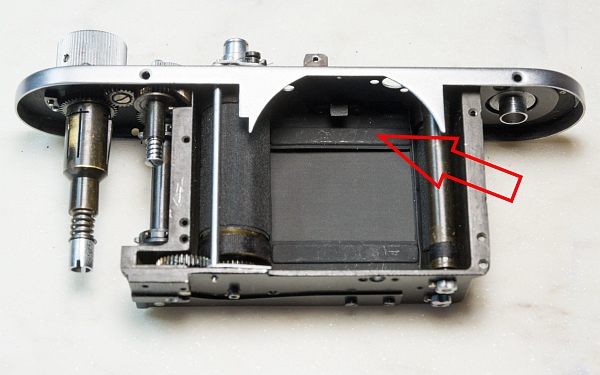

When attaching the rangefinder (Parts 31), make sure that the rangefinder arm has been inserted correctly (below).

The window for the vertical offset of the rangefinder is glued with shellac. After loosening it with alcohol, you can turn it to adjust the vertical offset or remove it completely to clean it.

The horizontal offset is adjusted with the small screw. When turned to the right, the rangefinder spot in the viewfinder moves towards infinity.

Now put the cover back on and screw on the shutter speed dial – done.

9. Result

All the effort was worth it! The camera looks great, is perfectly adjusted, and runs very smoothly.